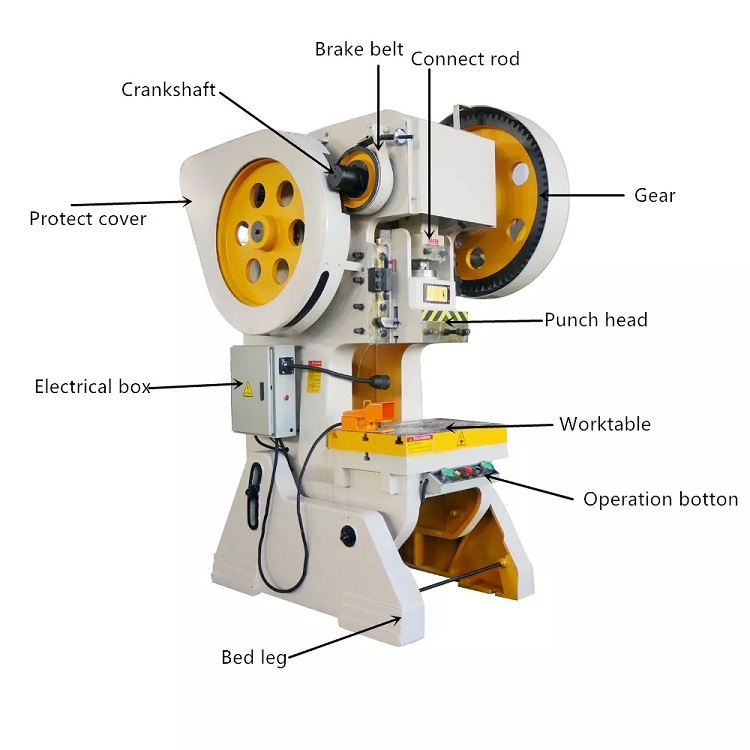

Working Principle

1.It adopts horizontally placed crankshaft.

2. The crankshaft position is equipped with travel adjustment device.

3. It also equipped with rigid turn-key type clutch.

4. The machine is die height manually adjusted and degree scale display

מִפרָט

סוּג | Normal pressure | Slipper stroke | Columns Distance | כּוֹחַ |

J23-10T | 100KN | 50 מ"מ | 160 מ"מ | 1.1kw |

J23-40T | 400KN | 100 מ"מ | 260mm | 4.0kw |

J23-63T | 630KN | 100 מ"מ | 280mm | 5.5kw |

J23-80T | 800KN | 120mm | 300mm | 7.5kw |

J21-100T | 1000KN | 130mm | 340mm | 7.5kw |

J21-125T | 1250KN | 140mm | 370mm | 11kw |

J21S-10T | 100KN | 50 מ"מ | 160 מ"מ | 1.1kw |

J21S-63T | 630KN | 100 מ"מ | 280mm | 5.5kw |

J21S-125T | 1250KN | 140 | 370mm | 11kw |

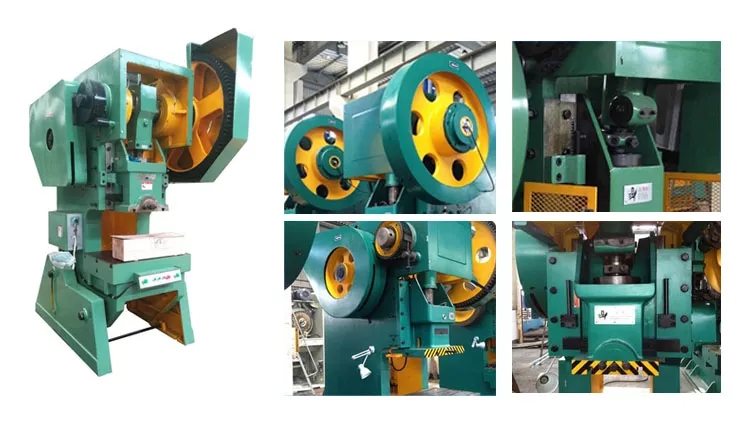

Punching machine

The press is applicable to compression of plastic materials. For example, powder and plastic products forming and heat/cool metal extruction, stamping, bending, edge-folding, straightening, depressed mounting and etc.

Independent drive structures and electrical devices insure reliable operation with centered control buttons. Adjustment ,manual operation and semi-automatic operation, three modes are provided respectively for your choice.

The working pressure, pressing speed, unload-descending speed and decelecrated pressing speed can be respectively adjusted in requirements. By preset, knock-out and drawing can be taken out with pressure-dependent or distance-dependent of die..